Hot Rolled Steel Sheet & Plate

Please select product dimensions

Preferred Pricing

Please select product dimensions

Preferred Pricing

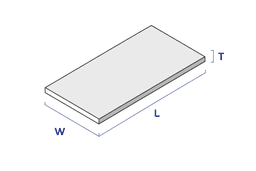

How to Measure

T = Thickness

W = Width

L = Length

Specifications

Hot rolled steel and sheet metal products are commonly used for industrial applications worldwide. With a wide range of options, HR plate and sheet metal products provide numerous advantages that other metal products cannot replicate.

To learn more about our hot rolled steel plate and sheet metal options, get in touch with our sales team to find the metal product that meets your project specifications. At IMS, our metal experts understand the requirements and advantages of our entire inventory of metal products. Let us help you with your metal needs today.

At IMS, we provide unsurpassed next-day delivery or same-day will-call pick-up at any of our convenient locations. We are well equipped to handle all-sized orders with seven locations and over 400,000 square feet of warehouse space. From selling one piece in our stores to delivering truckloads of metal to your location, we work well with all types of customers.

Hot rolling usually uses large ingots and large reduction rolling, improving production efficiency and creating conditions for increasing rolling speed and achieving a continuous and automated rolling process. Some of the other benefits associated with hot rolled steel square bar include:

Hot rolled steel plate and sheet typically require much less processing than cold rolled steel, making it much cheaper. However, since hot rolled steel can cool at room temperature, it’s free from internal stresses that can arise from quenching or work-hardening processes.

HR steel sheet and plate can be identified by the following characteristics:

Hot rolled steel sheet and plate provide a rougher surface than cold rolled steel and plate. It is also regularly used when galvanized in applications where corrosion resistance is necessary. High strength and highly formable HR steel plate and sheet metal products are easy to drill, form and weld.

The main differences between hot rolled and cold rolled steel are their specific manufacturing processes. Hot rolling refers to processing done with heat, while cold rolling refers to procedures done at or around room temperature.

Although these techniques affect overall performance and application, they should not be confused with formal specifications and grades of steel, which relate to metallurgical composition and performance ratings.

Both hot rolled steel and cold rolled steel start essentially the same way and can have the same grades and specifications. But cold rolled steel undergoes additional processing steps, resulting in improved properties that can be exploited for different applications. Each type of steel has its advantages and disadvantages, and costs for the two types of steel can also vary widely.

When you order from Industrial Metal Supply (IMS), we can cut your metal to size and deliver it the next day. If you require more extensive services than just sawing or shearing, we also offer the following advanced metal cutting options:

Ordering

With seven locations located throughout the greater Los Angeles area, Orange County, Inland Empire, San Diego and Phoenix and Tucson, Arizona, IMS is a full-service metal supplier that understands what you need. Our inventory of metal products includes a broad range of metal shapes and an extensive selection of alloys. We offer the following advantages:

Stop by one of our seven locations across California and Arizona and check out our hot rolled steel sheet and plate metal inventory. We offer quick delivery throughout California, Arizona, Nevada, and Northern Mexico. Request a quote or contact IMS for high-quality hot rolled plate steel and sheet metal today.

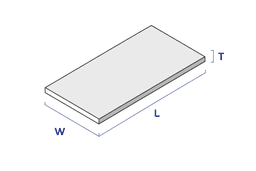

How to Measure

T = Thickness

W = Width

L = Length

Specifications

Hot rolled steel and sheet metal products are commonly used for industrial applications worldwide. With a wide range of options, HR plate and sheet metal products provide numerous advantages that other metal products cannot replicate.

To learn more about our hot rolled steel plate and sheet metal options, get in touch with our sales team to find the metal product that meets your project specifications. At IMS, our metal experts understand the requirements and advantages of our entire inventory of metal products. Let us help you with your metal needs today.

At IMS, we provide unsurpassed next-day delivery or same-day will-call pick-up at any of our convenient locations. We are well equipped to handle all-sized orders with seven locations and over 400,000 square feet of warehouse space. From selling one piece in our stores to delivering truckloads of metal to your location, we work well with all types of customers.

Hot rolling usually uses large ingots and large reduction rolling, improving production efficiency and creating conditions for increasing rolling speed and achieving a continuous and automated rolling process. Some of the other benefits associated with hot rolled steel square bar include:

Hot rolled steel plate and sheet typically require much less processing than cold rolled steel, making it much cheaper. However, since hot rolled steel can cool at room temperature, it’s free from internal stresses that can arise from quenching or work-hardening processes.

HR steel sheet and plate can be identified by the following characteristics:

Hot rolled steel sheet and plate provide a rougher surface than cold rolled steel and plate. It is also regularly used when galvanized in applications where corrosion resistance is necessary. High strength and highly formable HR steel plate and sheet metal products are easy to drill, form and weld.

The main differences between hot rolled and cold rolled steel are their specific manufacturing processes. Hot rolling refers to processing done with heat, while cold rolling refers to procedures done at or around room temperature.

Although these techniques affect overall performance and application, they should not be confused with formal specifications and grades of steel, which relate to metallurgical composition and performance ratings.

Both hot rolled steel and cold rolled steel start essentially the same way and can have the same grades and specifications. But cold rolled steel undergoes additional processing steps, resulting in improved properties that can be exploited for different applications. Each type of steel has its advantages and disadvantages, and costs for the two types of steel can also vary widely.

When you order from Industrial Metal Supply (IMS), we can cut your metal to size and deliver it the next day. If you require more extensive services than just sawing or shearing, we also offer the following advanced metal cutting options:

Ordering

With seven locations located throughout the greater Los Angeles area, Orange County, Inland Empire, San Diego and Phoenix and Tucson, Arizona, IMS is a full-service metal supplier that understands what you need. Our inventory of metal products includes a broad range of metal shapes and an extensive selection of alloys. We offer the following advantages:

Stop by one of our seven locations across California and Arizona and check out our hot rolled steel sheet and plate metal inventory. We offer quick delivery throughout California, Arizona, Nevada, and Northern Mexico. Request a quote or contact IMS for high-quality hot rolled plate steel and sheet metal today.